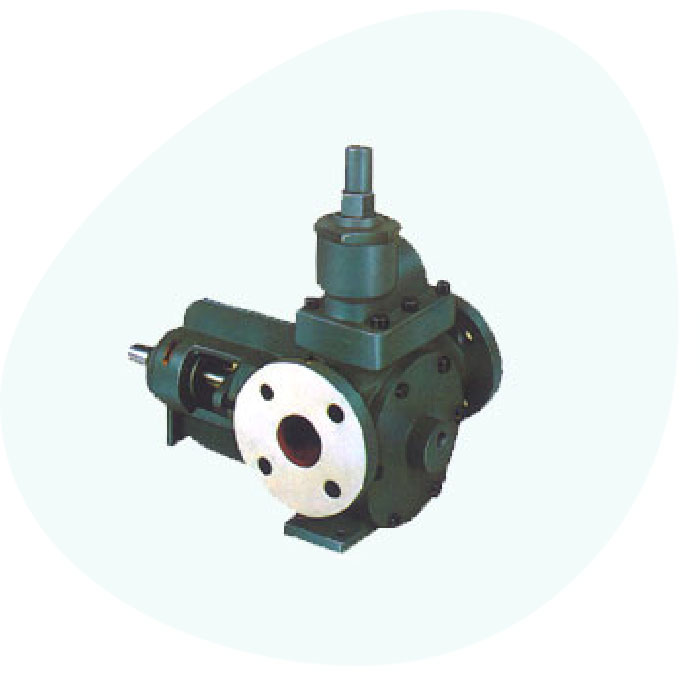

Shuttle Block Pumps

Working Principle

TUSHACO Shuttle Block series employs a unique pumping principle - a combination of Rotary and Piston Pump. Two double acting pistons in their respective slots at right angles to each other accomplish this, while the rotor turns without the need for any valving. The Shuttle Block pump is a self-priming Rotary pump.

There are only three pumping elements - Rotor, Piston and Shuttle. Rotor is keyed to a single shaft and runs concentric in pump casing. It has a rectangular slot across its face. The channel-shaped piston reciprocates within this slot. A rectangular block, shuttle, fits liquid tight in piston slot and reciprocates. The rotary action of rotor combined with the eccentrically mounted shuttle creates reciprocating motion among the pumping elements.

Like a true piston pump, this pump can handle highly viscous liquids with unmatched suction characteristics and yet smoothly without pulsation. This pumping principle - unlike centrifugal or gear pumps - gently handles the product without breaking it down, emulsifying, foaming, chewing or heating: an added advantage at no extra cost. Such a simple construction has resulted in extremely rugged and maintenance-free pumps with very low noise levels. Most of the difficult pumping problems can be overcome by a Shuttle Block Pump. View Catalogue

There are only three pumping elements - Rotor, Piston and Shuttle. Rotor is keyed to a single shaft and runs concentric in pump casing. It has a rectangular slot across its face. The channel-shaped piston reciprocates within this slot. A rectangular block, shuttle, fits liquid tight in piston slot and reciprocates. The rotary action of rotor combined with the eccentrically mounted shuttle creates reciprocating motion among the pumping elements.

Like a true piston pump, this pump can handle highly viscous liquids with unmatched suction characteristics and yet smoothly without pulsation. This pumping principle - unlike centrifugal or gear pumps - gently handles the product without breaking it down, emulsifying, foaming, chewing or heating: an added advantage at no extra cost. Such a simple construction has resulted in extremely rugged and maintenance-free pumps with very low noise levels. Most of the difficult pumping problems can be overcome by a Shuttle Block Pump. View Catalogue