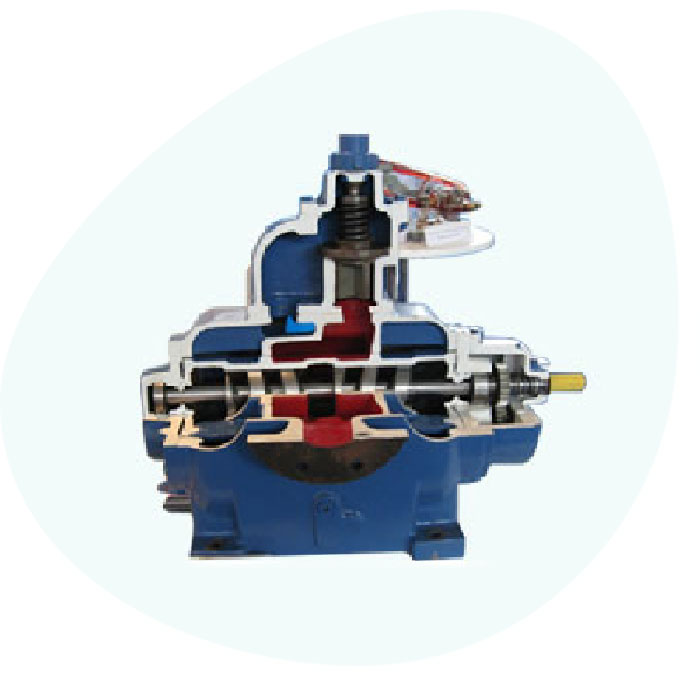

Two Screw Pumps

Two screw pumping technology was invented by William Quimby of New Jersey, U.S.A in the year 1894. He founded a manufacturing unit of two screw pump which was eventually acquired by Warren Pumps an associate company of Tushaco Pumps in the year 1950.

Working Principle

A pair of specially profiled screws, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners. Each screw set has one RH and one LH screw engaging with a similar but opposite hand screw pair.

A pair of hardened and profile ground timing gears synchronize the screws to maintain a small but positive clearance between the flanks thus ensuring no metal to metal contact. The pumps can, therefore, run dry for sometime without any damage. This unique feature enables to run the pump even dry and handle fluids that do not have enough lubricating value and also very low or high viscous products. Consequently, since there is no metal to metal contact; wear and tear is reduced to the minimum, ensuring extremely long service life. With two pairs of screws running in the same casing, the internal velocities are very small - consequently the NPSH R is practically the lowest even when the pumps run at motor speeds and while handling viscous products. Opposed screw pitches totally eliminate axial thrusts. Relatively small diameters of screws enables the pump to operate at high speeds directly coupled to prime movers - without the need for speed reducers even while handling high viscous fluids. The seals are always under suction pressure, thus making use of simple, inexpensive seals. The axial flow is without turbulence, rotation, churning, chewing guarantees gentle handling of products. Noise and vibration levels are the lowest. Positive clearance between running parts makes it easier to construct the pump in different materials safely, especially in stainless steel, without the fear of seizing. Thus a variety of fluids can easily be handled by selecting the right materials of construction. View Catalogue

A pair of hardened and profile ground timing gears synchronize the screws to maintain a small but positive clearance between the flanks thus ensuring no metal to metal contact. The pumps can, therefore, run dry for sometime without any damage. This unique feature enables to run the pump even dry and handle fluids that do not have enough lubricating value and also very low or high viscous products. Consequently, since there is no metal to metal contact; wear and tear is reduced to the minimum, ensuring extremely long service life. With two pairs of screws running in the same casing, the internal velocities are very small - consequently the NPSH R is practically the lowest even when the pumps run at motor speeds and while handling viscous products. Opposed screw pitches totally eliminate axial thrusts. Relatively small diameters of screws enables the pump to operate at high speeds directly coupled to prime movers - without the need for speed reducers even while handling high viscous fluids. The seals are always under suction pressure, thus making use of simple, inexpensive seals. The axial flow is without turbulence, rotation, churning, chewing guarantees gentle handling of products. Noise and vibration levels are the lowest. Positive clearance between running parts makes it easier to construct the pump in different materials safely, especially in stainless steel, without the fear of seizing. Thus a variety of fluids can easily be handled by selecting the right materials of construction. View Catalogue